There are certain points to be noted which we have discovered while re-searching more than 30

mines and expert’s sharing their experience while dealing in Low EC Quartz for semi-conductor and

crucible industry.

- Typically, the EC levels means electronic conductivity which have been majorly found are ranging from 3.5-5.0 S/cm for crucible/semi-conductor grade Quartz Lumps.

- The most important factor before choosing right mines for crucible quartz is the application of the Quartz for the particular industry. In crucible industry there are three layers of the crucible and the Manufacturers are very concerned about specifications and parameters as lower impurity material is highly preferable with less iron and alumina content with few other impurities.

- The requirements and demand for 99.99% have been increased for a while but the actual mines are very rare who can consistently supply 99.99% sio2 on large contractual basis from a single mine.

- Due to ppm/ percentage variation of testing methods there are various results coming in Indian and Chinese laboratories. Best way to measure the Quartz is by testing them and with a production of Middle and outer layer of crucible with testing process.

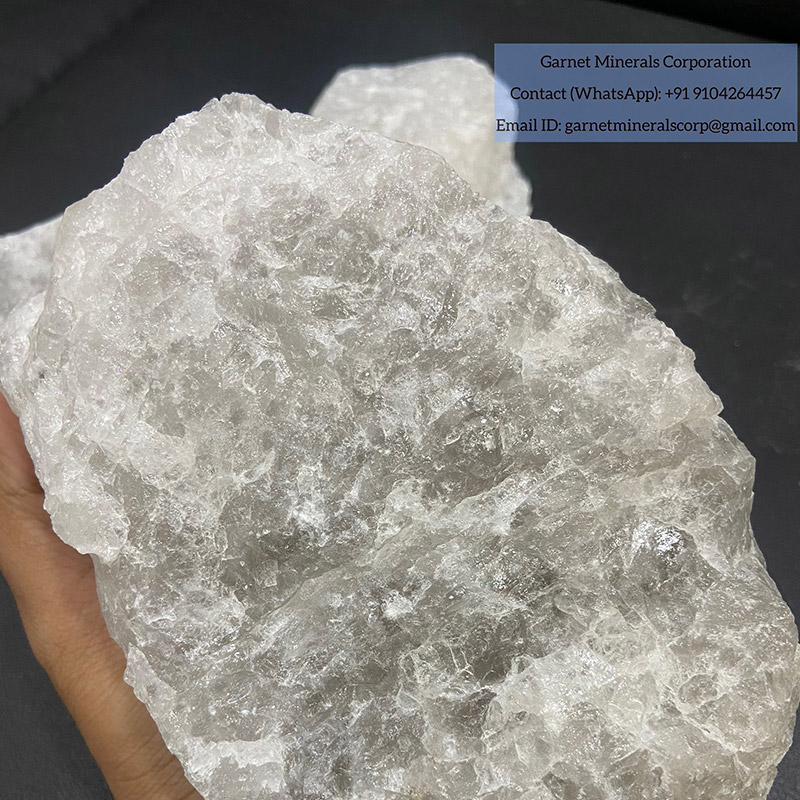

- There is also lot depending upon required structure of quartz for most quartz which have been successfully used for making crucible are granular in structure while glassy structure is preferred for photovoltaic purposes.

- There are many companies who prefer to purchase ROM one feet boulders of high-grade Quartz where it becomes convenient for miner to supply in huge quantity, loss of material is very nominal and also consistency is very high in terms of the Quality of the high-grade Quartz.

- We have High purity quartz which have been proven to be High purity low PPM Impurity material with 99.9% silica (minimum). Kindly refer to our product details & share your requirement details on our email id or what’s App by the given contact Number.